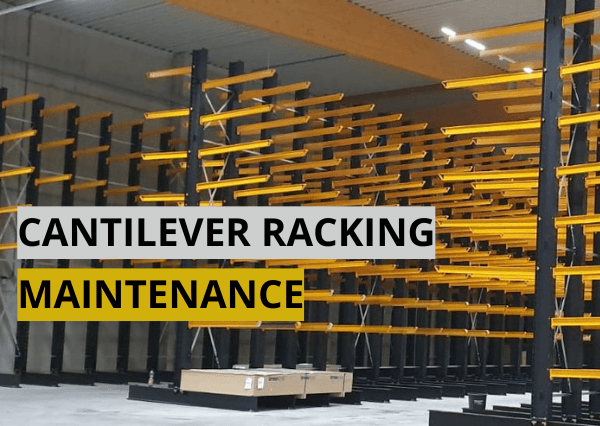

A well-built racking system is only as safe as its maintenance routine. Every day, cantilever racking carries heavy, awkward loads that test its strength and stability. Over time, even minor knocks from a forklift or exposure to the elements can weaken key components — turning a reliable structure into a potential safety risk if left unchecked.

Cantilever racking maintenance isn’t just another task on the warehouse checklist. It’s a critical process that protects your people, your stock, and your investment in your storage system.

Table of Contents

What Cantilever Racking Maintenance Involves

Cantilever racking is designed for long, bulky items like steel, timber, or piping — using upright columns and cantilever arms to carry the load. Maintenance keeps these load-bearing points in top condition, ensuring each arm, base plate and upright column can safely support its rated capacity.

A thorough maintenance programme should include:

- Regular inspections to identify impact damage, corrosion, rust or loose fixings on base components and upright columns.

- Verification of load notices to ensure the racking is used within its designed load capacities.

- Checks on safety accessories, such as safety guards, beam locks and end stops.

- Repair work or replacement using OEM parts when damage is detected.

- Compliance checks with SEMA Guidelines, EN 15635, and other UK legislation including PUWER 1998 and the Health and Safety at Work Act 1974.

- Record keeping and reporting to support the Person Responsible for Racking Safety (PRRS).

(The PRRS is the individual in your organisation tasked with overseeing racking safety. Under SEMA and EN 15635 guidelines, they ensure inspections are carried out, damage is recorded, and the system is used safely within its rated load capacity. In short, they’re your first line of defence against unsafe racking.)

By following SEMA’s codes of practice and keeping inspection records up to date, you ensure both safety and regulatory compliance — two things that every warehouse should take seriously.

The Risks of Poor or Irregular Maintenance

When maintenance slips down the priority list, small problems quickly turn into major hazards. Impact damage from forklifts, corrosion in outdoor storage yards, or missing load notices might not seem urgent, but they all affect structural integrity.

Ignoring maintenance can lead to:

- Increased safety risks from weakened or overloaded structures.

- Regulatory breaches under EN 15635 and HSG76 Warehousing and Storage guidance.

- Higher repair costs from progressive damage that could have been caught early.

- Unplanned downtime if racking must be cordoned off or dismantled after failure.

- Reduced efficiency through restricted access or lower storage capacity.

A damaged or overloaded rack isn’t always easy to spot — especially with heavy-duty cantilever racking where stress points are hidden within the arms and base plates. That’s why scheduled inspections by trained professionals are essential.

How Ashford Retail Services Helps

Ashford Retail Services provides nationwide racking inspection and maintenance support for cantilever, pallet and adjustable pallet racking systems. Our team is trained to SEMA standards and understands the practical realities of busy warehouse operations.

We provide:

- Routine cantilever racking inspections by SEMA Approved Racking Inspectors, using a traffic-light classification system to prioritise repairs.

- Comprehensive reporting that highlights safety risks, repair requirements and compliance notes.

- Racking repairs and re-profiling, including upright column replacement, base plate repair and structural adjustments.

- Preventive treatments such as rust-proofing, weather-resistant coatings and component replacement to extend service life.

- Guidance and training for warehouse personnel, including Rack Safety Awareness and Racking Maintenance Training Courses.

- Support for PRRS roles, ensuring you meet the obligations set out in the SEMA Code of Practice and UK legislation.

All maintenance work is carried out to the highest standards of safety, quality and regulatory compliance — helping you meet requirements under the Health and Safety at Work Act 1974, Workplace (Health, Safety & Welfare) Regulations 1992, and the Working at Height Regulations 2005.

Building Maintenance Into Your Warehouse Routine

A simple, proactive maintenance plan saves both time and money. Begin by assigning a Person Responsible for Racking Safety and ensuring they have access to all inspection and repair records. Establish a clear schedule for routine checks — typically once every 6 to 12 months depending on usage and traffic levels.

Between professional inspections, encourage warehouse personnel to carry out visual safety checks for any obvious damage or corrosion. When issues are spotted early, repair costs are lower and safety standards remain high.

Arrange Your Next Inspection

Regular maintenance keeps your racking systems safe, compliant and working efficiently. If it’s been a while since your last inspection, now’s the time to act.

Ashford Retail Services can assess your cantilever racking, identify areas of concern and provide clear recommendations to help you stay compliant with SEMA Guidelines and EN 15635.

Book a cantilever racking inspection today — and make maintenance part of your long-term warehouse safety strategy.

Contact Ashford Retail Services to arrange your next inspection or speak to our team about racking repairs, safety accessories and ongoing maintenance support.